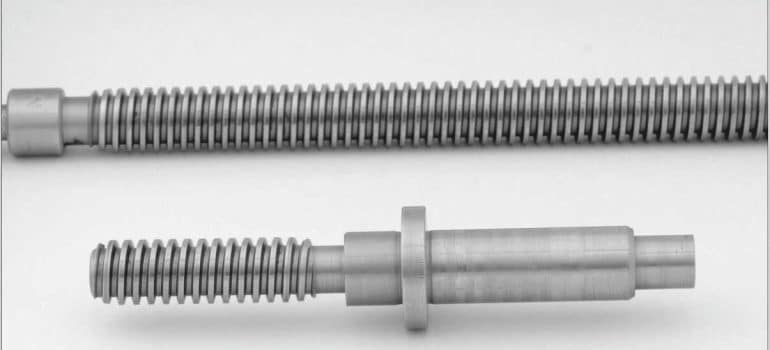

Trends And Innovations In Non-Automotive Parts Manufacturing

The world of manufacturing is constantly evolving as well as non-automotive parts manufacturing is no exception. While the auto industry continues to be a major driver of innovation, exciting advancements are happening across various non-automotive sectors. Let’s explore some of the significant trends influencing the future of manufacturing non-automotive parts:

Diversification of Materials:

Traditionally, metals and plastics have dominated the non-automotive parts landscape. However, we’re witnessing a surge in the use of advanced materials like:

- Composites: These lightweight, high-strength materials are finding applications in everything from aerospace components to sporting goods. Composites combine a distinct mix of characteristics, rendering them well-suited for rigorous applications.

- Bioplastics: With a growing focus on sustainability, bioplastics derived from renewable resources are gaining traction. These eco-friendly materials offer a viable alternative to traditional plastics in various applications, like packaging as well as consumer goods.

- 3D Printing filaments: The rise of additive manufacturing (3D printing) has opened doors for a wider range of materials to be used for parts creation. This allows for customization and the creation of complex geometries not possible with traditional methods.

Smart Manufacturing and Automation:

The integration of automation and Industry 4.0 principles is transforming how non-automotive parts are manufactured. Here’s how:

- Industrial robots: Robots are taking over repetitive and dangerous tasks, increasing production efficiency and worker safety.

- Smart machines: Machines equipped with sensors and connected to the Industrial Internet of Things (IIoT) can monitor performance, predict maintenance needs as well as optimize production processes.

- Data Analytics: Manufacturers are leveraging data analytics to gain valuable insights into their operations. This allows for better decision-making regarding production scheduling, inventory management and resource allocation.

Focus on Sustainability:

Environmental consciousness is a driving force in non-automotive parts manufacturing. Here are some key trends:

- Sustainable materials: As mentioned earlier, the shift towards bioplastics and other eco-friendly materials is a crucial step towards a more sustainable future.

- Energy-efficient processes: Manufacturers are adopting energy-saving technologies as well as optimizing production processes to minimize their environmental footprint.

- Circular economy principles: The concept of a circular economy, where materials are reused and recycled, is gaining traction.This minimizes waste and encourages the preservation of resources.

Customization and On-Demand Manufacturing:

The rise of e-commerce as well as the increasing demand for personalized products are pushing non-automotive parts manufacturers towards:

- Mass customization: Manufacturing processes are becoming more flexible to accommodate shorter production runs and customized products.

- Additive manufacturing: 3D printing allows for on-demand production of parts, catering to specific customer needs and reducing inventory requirements.

The Future of Non-Automotive Parts Manufacturing

These trends highlight the dynamic nature of non-automotive parts manufacturing. Embracing these innovations will be crucial for manufacturers to stay competitive as well as meet the evolving demands of the market. As technology continues to advance, we can expect even more exciting developments in materials, automation and sustainability, shaping the future of non-automotive parts creation.

Conclusion

Non-automotive parts manufacturing is rapidly evolving with advancements in materials, automation, sustainability and customization. Enhanced materials like composites and bioplastics improve performance and eco-friendliness, while automation enhances efficiency and safety. Sustainability efforts focus on eco-friendly materials and energy efficiency as well as customization meets consumer demands. Embracing these trends is vital for staying competitive, with ongoing technological advancements promising further innovation in the field. For more such insights, keep up with Pivot Fabrique